In today’s dynamic market reality, where time and precision are of paramount importance, modern WMS (Warehouse Management System) systems are becoming an indispensable tool. They make it possible to monitor every stage of the warehouse process. Implementing a WMS enables accurate inventory tracking, eliminating errors in warehouse processes and optimising space, resulting in increased efficiency and cost reduction. If you want to find out how our WMS can revolutionise the management of your warehouse, see our offer and contact us now.

Benefits of WMS implementation

A warehouse management system provides numerous benefits that improve the efficiency, accuracy and productivity of warehouse processes. The most important of these are listed below:

- order processing precision – advanced mechanisms allow order picking accuracy of more than 99%, which reduces errors and affects on-time delivery. This reduces the risk of mistakes and delays, which is crucial in order processing;

- integration with warehouse automation – WMS systems assume the possibility of combining the system with modern technologies, such as conveyor systems, warehouse robotics or automatic sorting systems., Integration with warehouse automation makes processes faster and more precise;

- Optimisation of logistics processes – intelligent algorithms support the processes of receiving, storage, picking, packing and shipping, leading to better inventory management and increased warehouse throughput, as well as supporting logistics planning. WMS implies optimisation of these processes, resulting in higher levels of efficiency and time savings;

- Maximise employee productivity – WMS systems offer tools such as voice technology, warehouse management systems, labour or dynamic task allocation to help optimise the use of human resources and automate repetitive activities. This results in better supply planning. This allows staff to focus on more demanding tasks, increasing their efficiency.

With these benefits, the warehouse WMS not only improves the customer experience, but also significantly reduces operational costs and lead times, supporting demand planning, which has a huge impact on a company’s profitability.

Key functions of a WMS

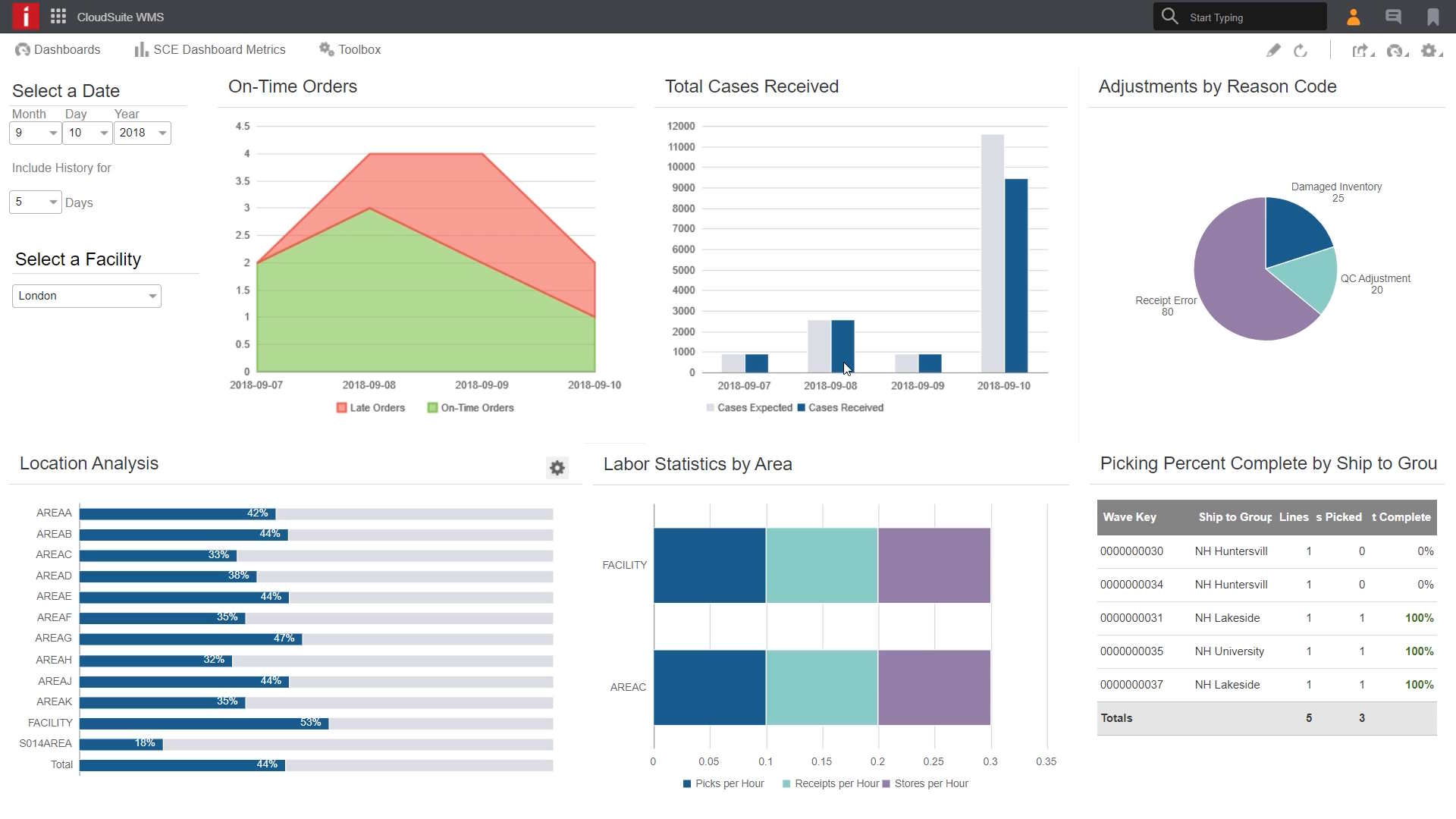

The WMS software offers a range of features that support warehouse management and increase efficiency. Below are the key features that are available in this system:

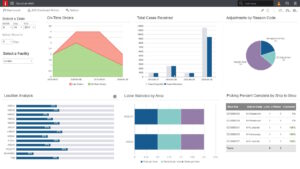

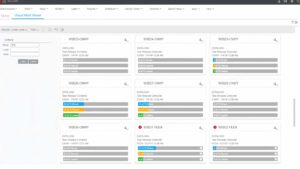

- stock management – full control over stock levels in multiple locations, real-time tracking of logistic units and automatic replenishment based on advanced analyses. With WMS systems, the company always has up-to-date information on stock levels and can manage the warehouse efficiently;

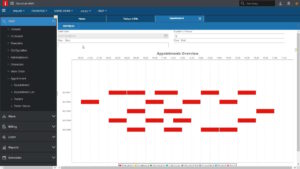

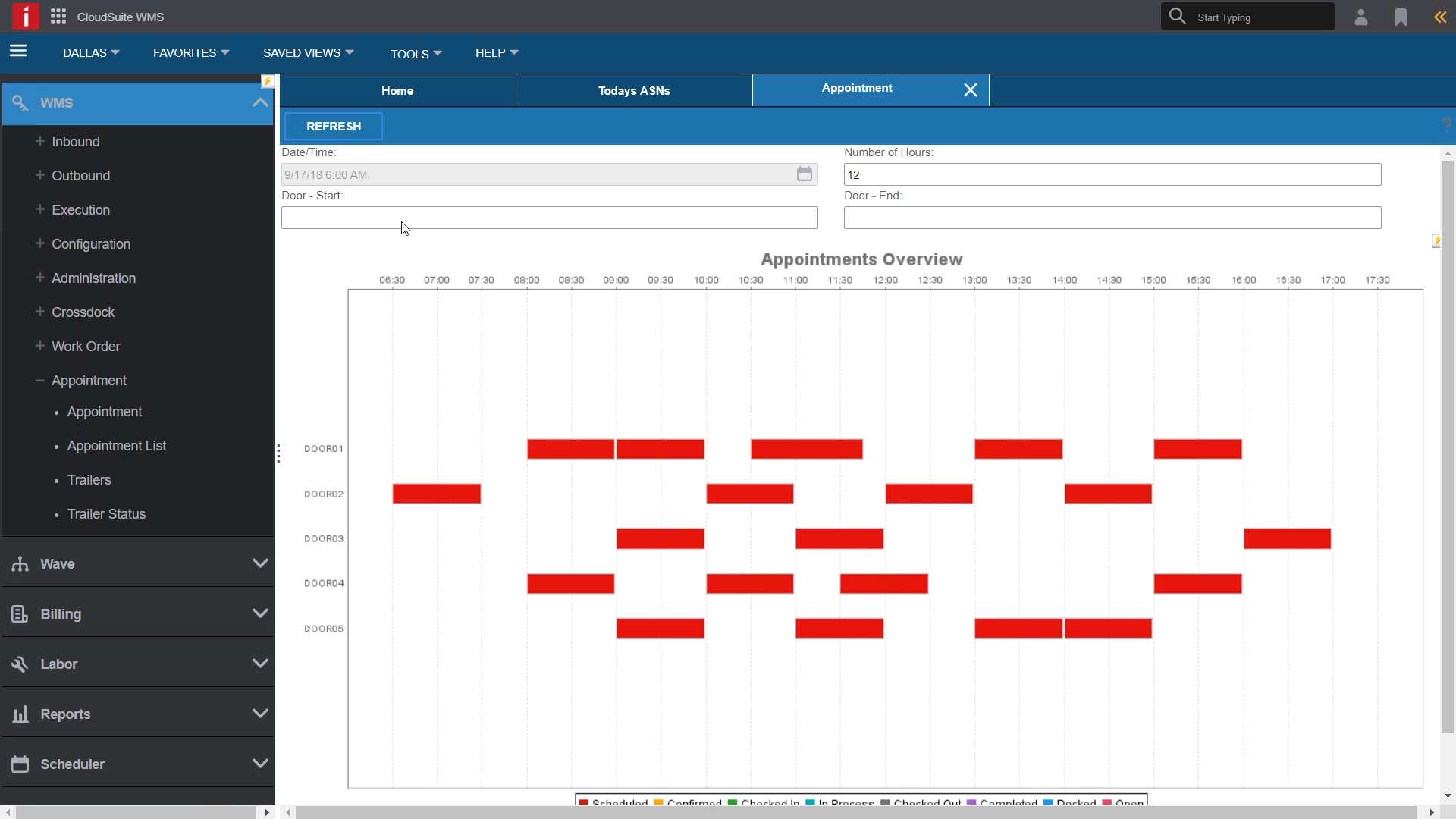

- streamlined receiving and storage – the WMS software implies dock scheduling systems, quality control, cross-docking and directed storage. These minimise storage time and increase operational efficiency. Improved organisation of goods receipt translates into faster processing and less risk of storage errors;

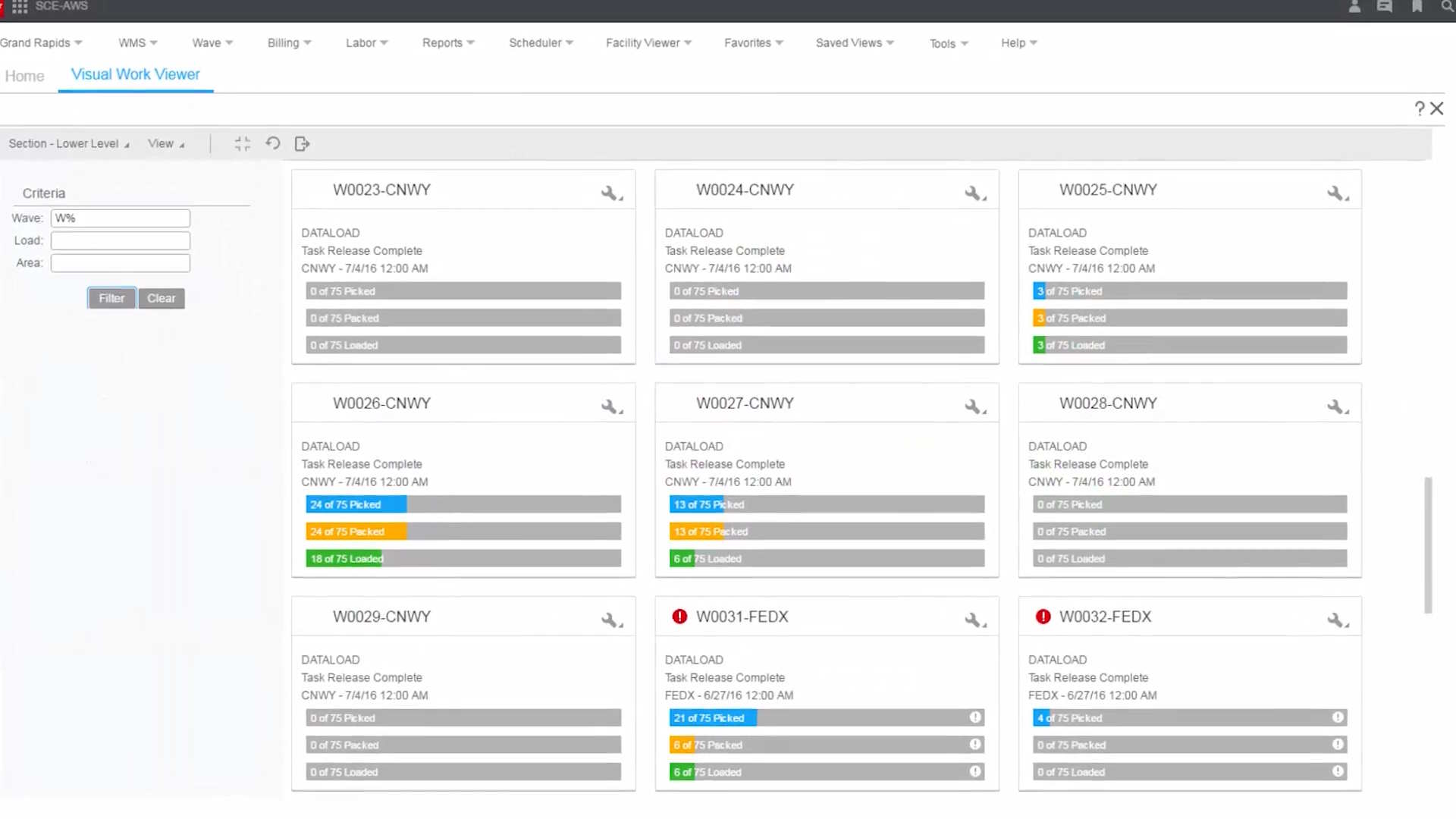

- order picking management – dynamic creation of picking waves based on order priorities, product types or warehouse location, allow handling both B2B and B2C orders. With the implementation of a WMS, orders are processed faster and the picking process is more optimised;

- advanced picking methods – WMS systems also support various picking methods, such as cluster, wave, group or voice-controlled picking; they increase the efficiency of warehouse operations. Choosing the best method allows orders to be picked faster, improving the efficiency of the entire warehouse;

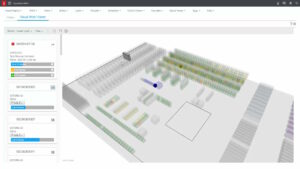

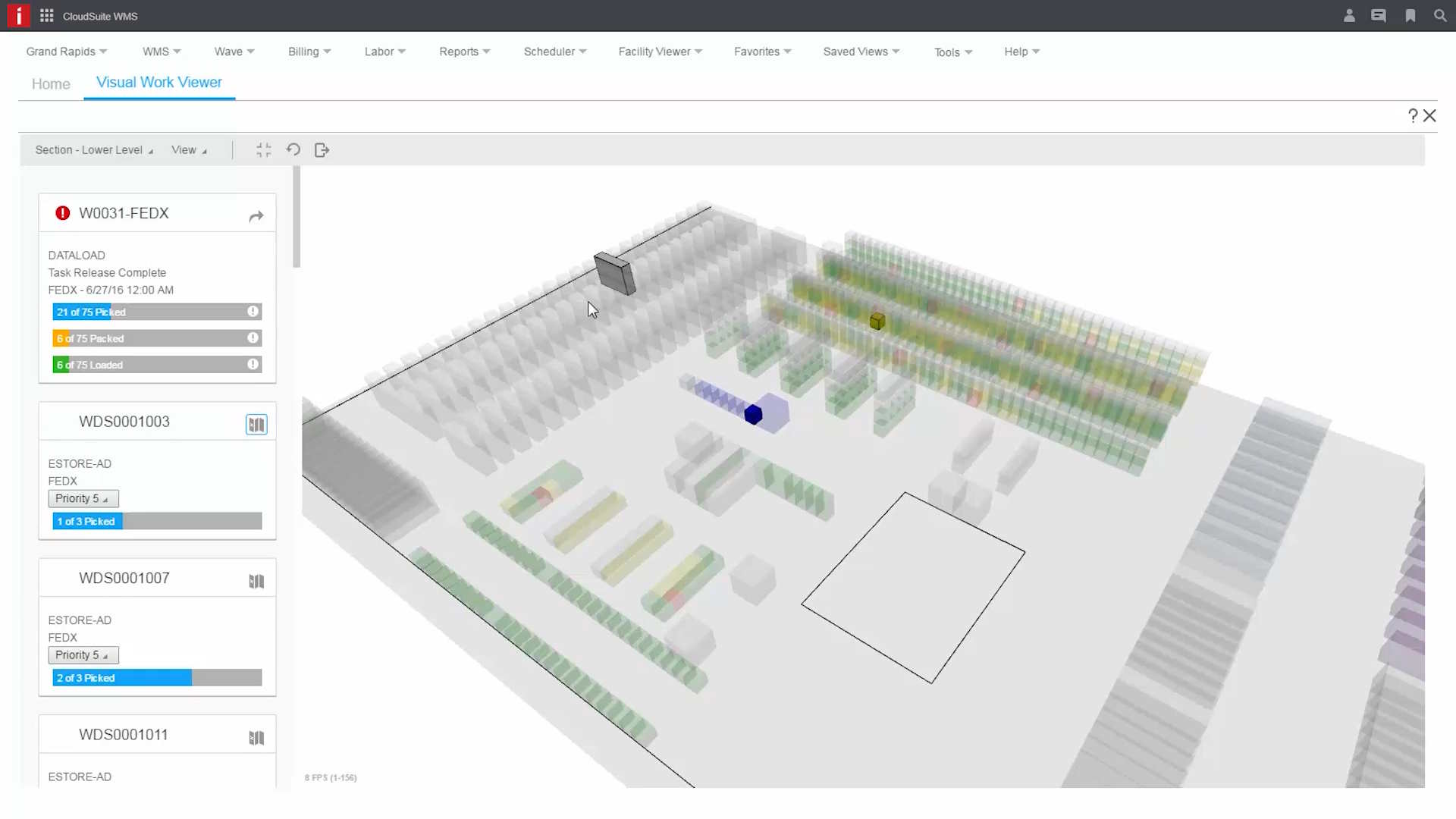

- 3D visualisation of the warehouse – interactive 3D models, which are part of WMS warehouse systems, make it possible to monitor warehouse processes in real time, identify bottlenecks and optimise workflows, which supports planning systems. This functionality enables faster detection of problems and implementation of solutions that improve warehouse operations;

- Value-added services – the WMS supports additional processes such as personalised packaging, labelling or product kitting, allowing orders to be tailored to individual customer needs. With these features, the company can offer a better service, meeting the specific requirements of customers;

- billing for logistics operators (3PL) – WMS class systems allow for simplified management of billing and cost estimates for logistics companies, ensuring accurate tracking of warehouse operations and effective invoicing of services. This function allows faster billing and minimises calculation errors, which is important in the daily management of a warehouse;

- labour management – WMS warehouse systems involve analysing the effectiveness of staff, optimising schedules and comparing actual lead times with set standards in order to improve operational efficiency. This functionality allows you to monitor the performance of your team on an ongoing basis and make changes that improve results.

With these features, warehouse management systems become an integral part of efficient warehouse management, enabling better operational performance and higher quality customer service.

Implementing a WMS – a step towards modern logistics

Implementing a WMS is a strategic investment that translates into improved customer service, optimised operating costs and increased efficiency of warehouse processes. Thanks to intelligent tools and automation, it is possible to dynamically adapt warehouse operations to changing market conditions.

Do you think that implementing a WMS is something ideal for your company? Or are you also interested in controlling systems? Contact us by e-mail info@cogit.pl or call +48 22 496 60 00 and our experts will be happy to answer your questions and help you choose the best solution.