Sales Planning

This is the first and fundamental module that initiates the entire S&OP process in the enterprise. It consists of three elements:

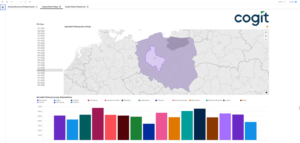

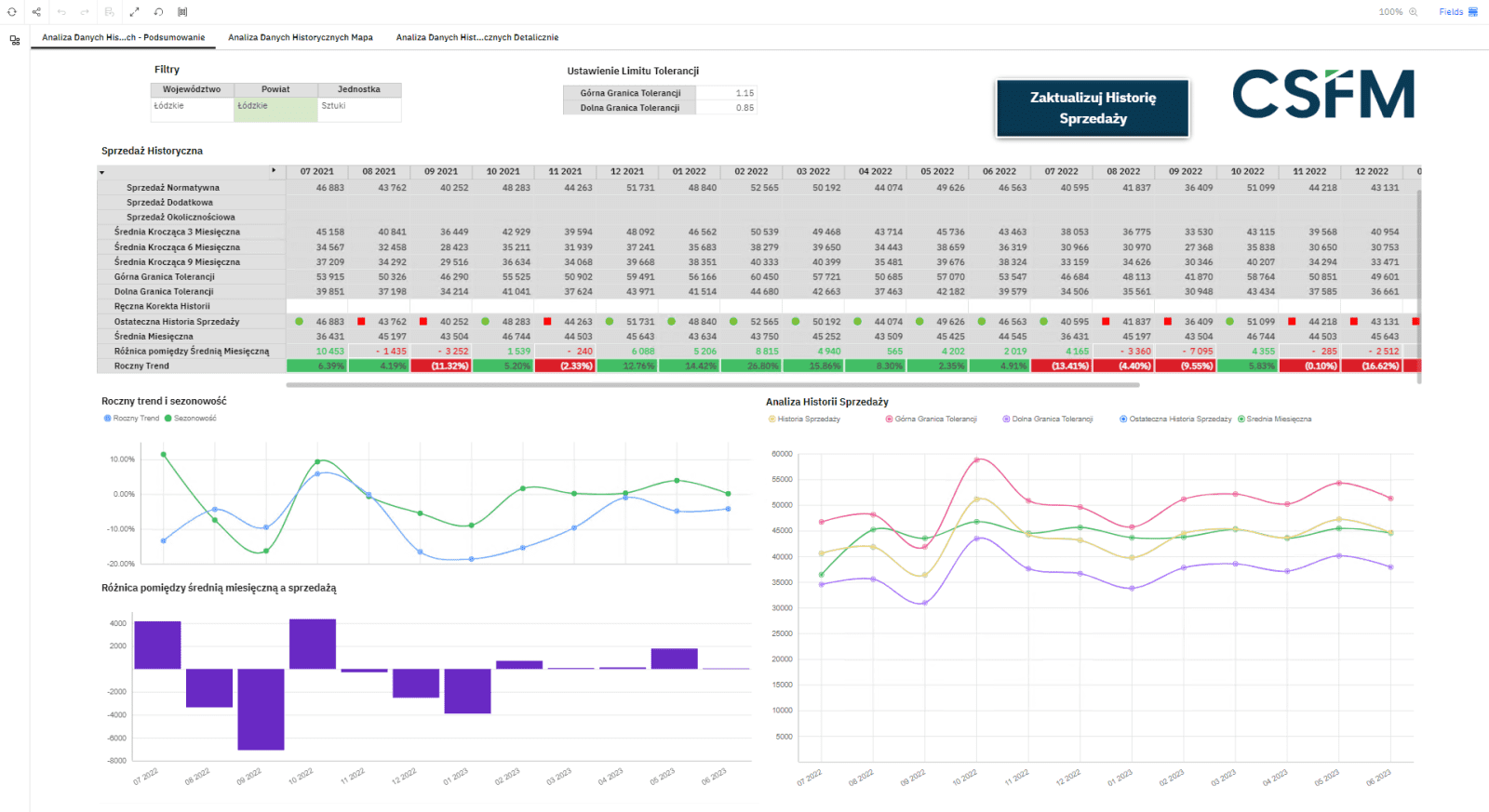

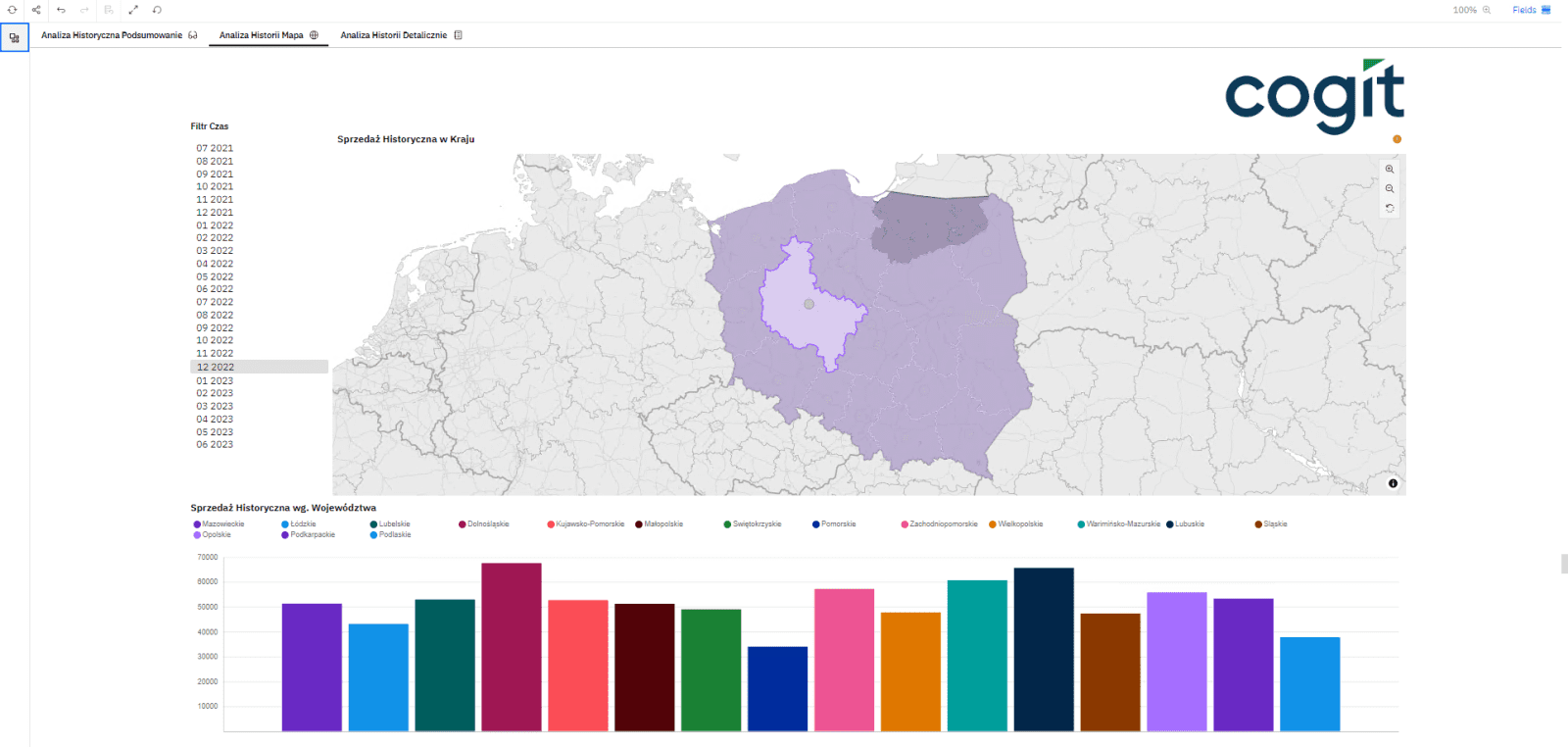

- Analysis of Historical Data – the initial stage of demand planning in the enterprise, where all information about historical sales is stored. Simple statistical algorithms are applied to determine trends, moving averages, and sales tolerance limits for different products in various markets.

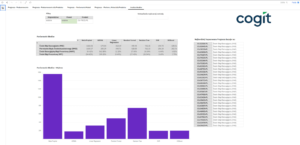

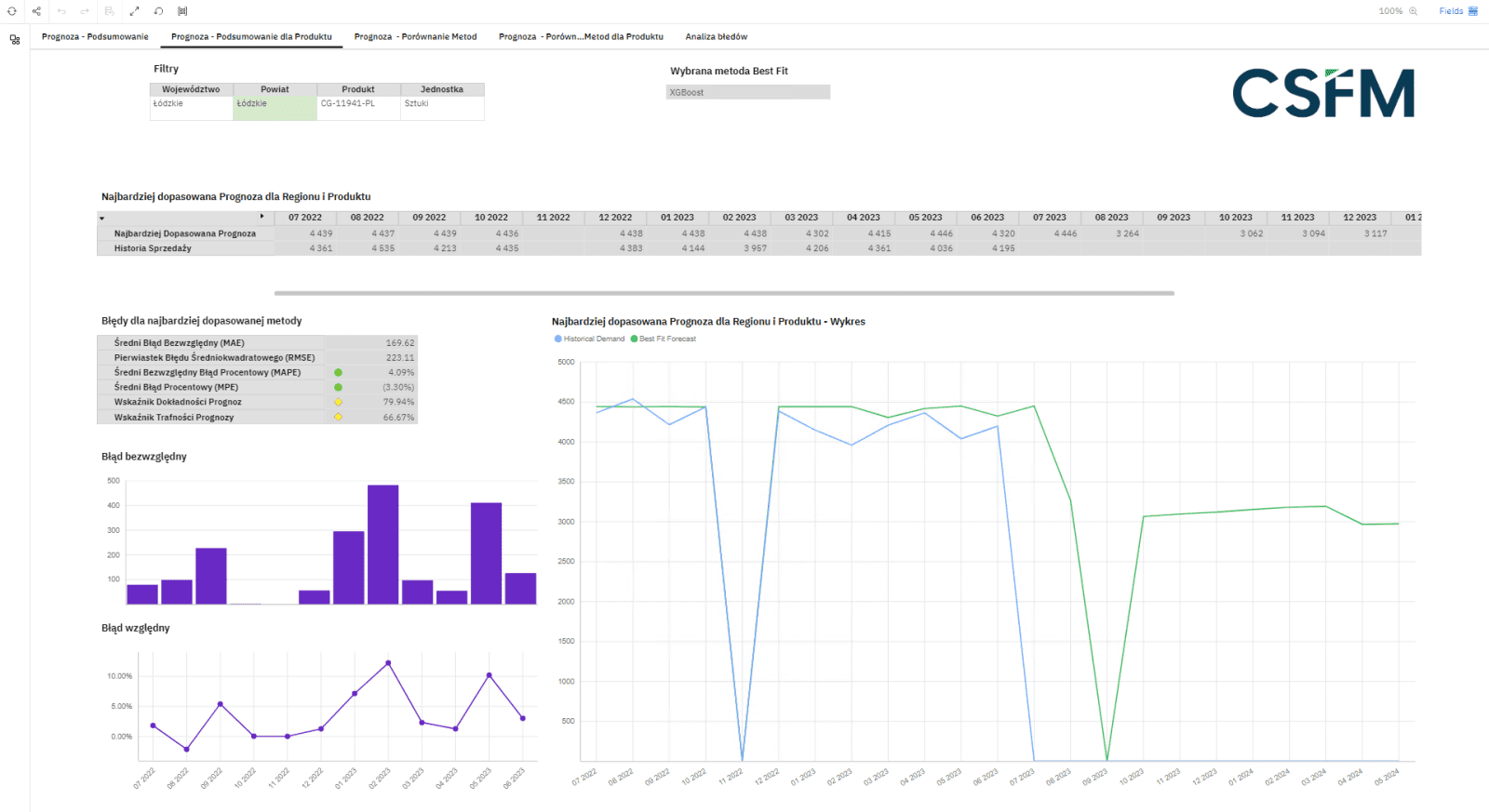

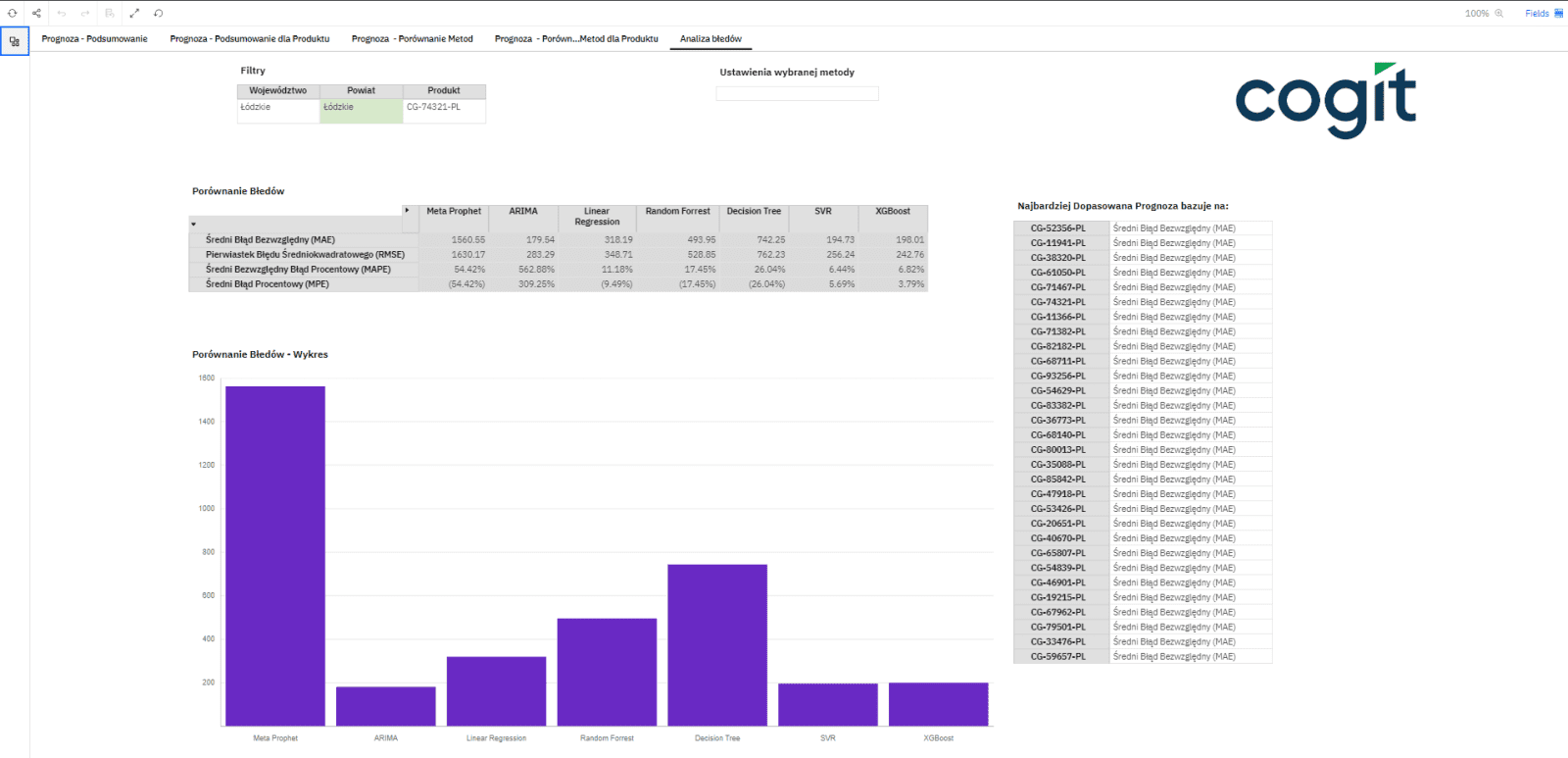

- Forecasting – the second stage in the demand planning process, involving a statistical approach to forecasting. Historical data is sent to Python, where a forecast is calculated using 7 methods, including Meta Prophet, ARIMA, Linear Regression, Random Forest, Decision Trees, SVR, and XGBoost. After calculating the forecast, the most fitting forecast is selected based on minimizing the error.

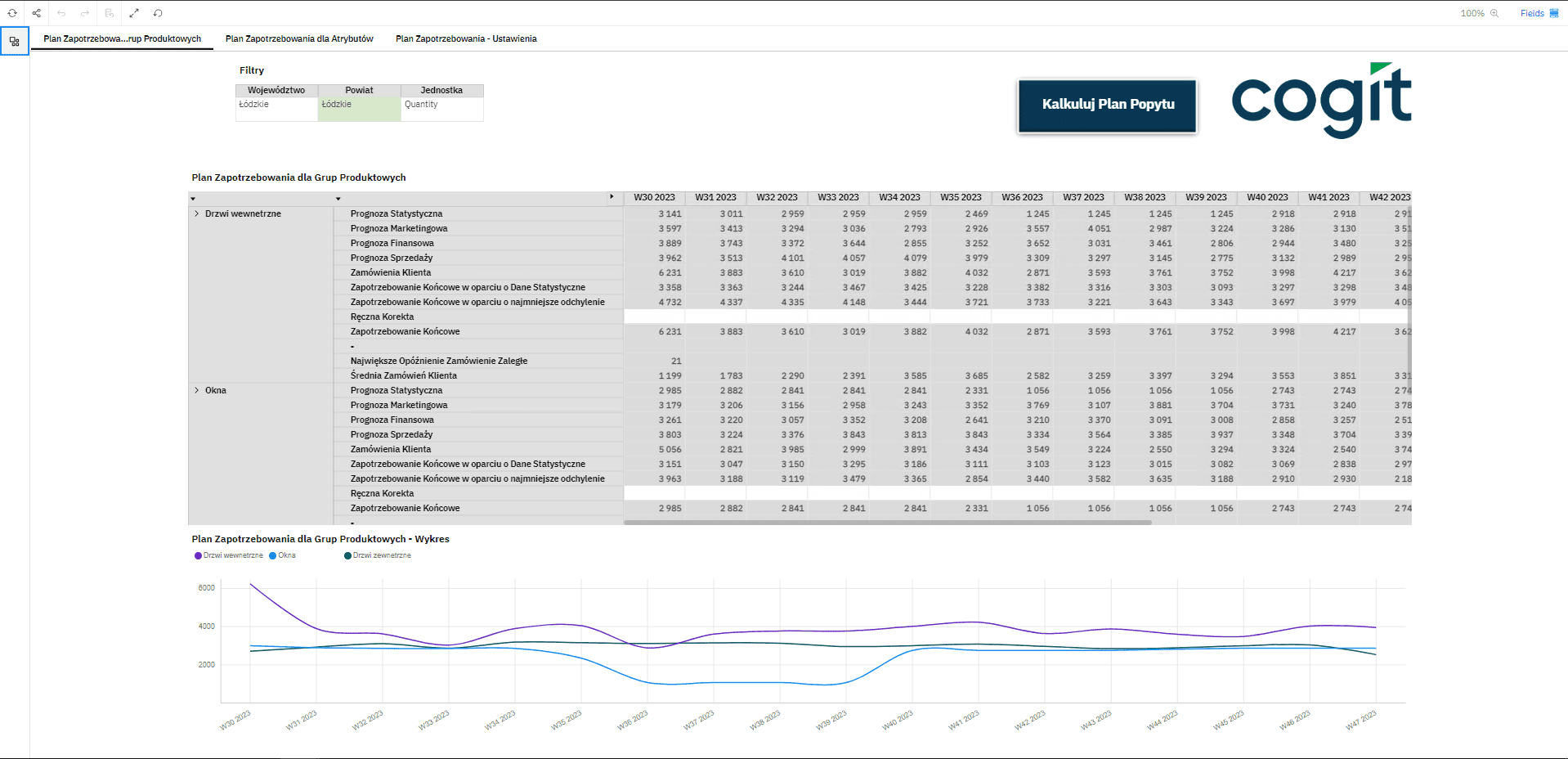

- Sales Plan – the final stage of this module. It provides information on the Statistical Forecast calculated in the “Forecasting” stage, offering insights into forecasts created by other departments such as marketing, finance, or sales, as well as customer orders.

The final demand can be based on the aforementioned forecasts or on the Statistical Model using the XGBoost algorithm. The “Golden Ratio” of all forecasts is selected based on past forecasts and their alignment with the final demand.

Warehouse Planning

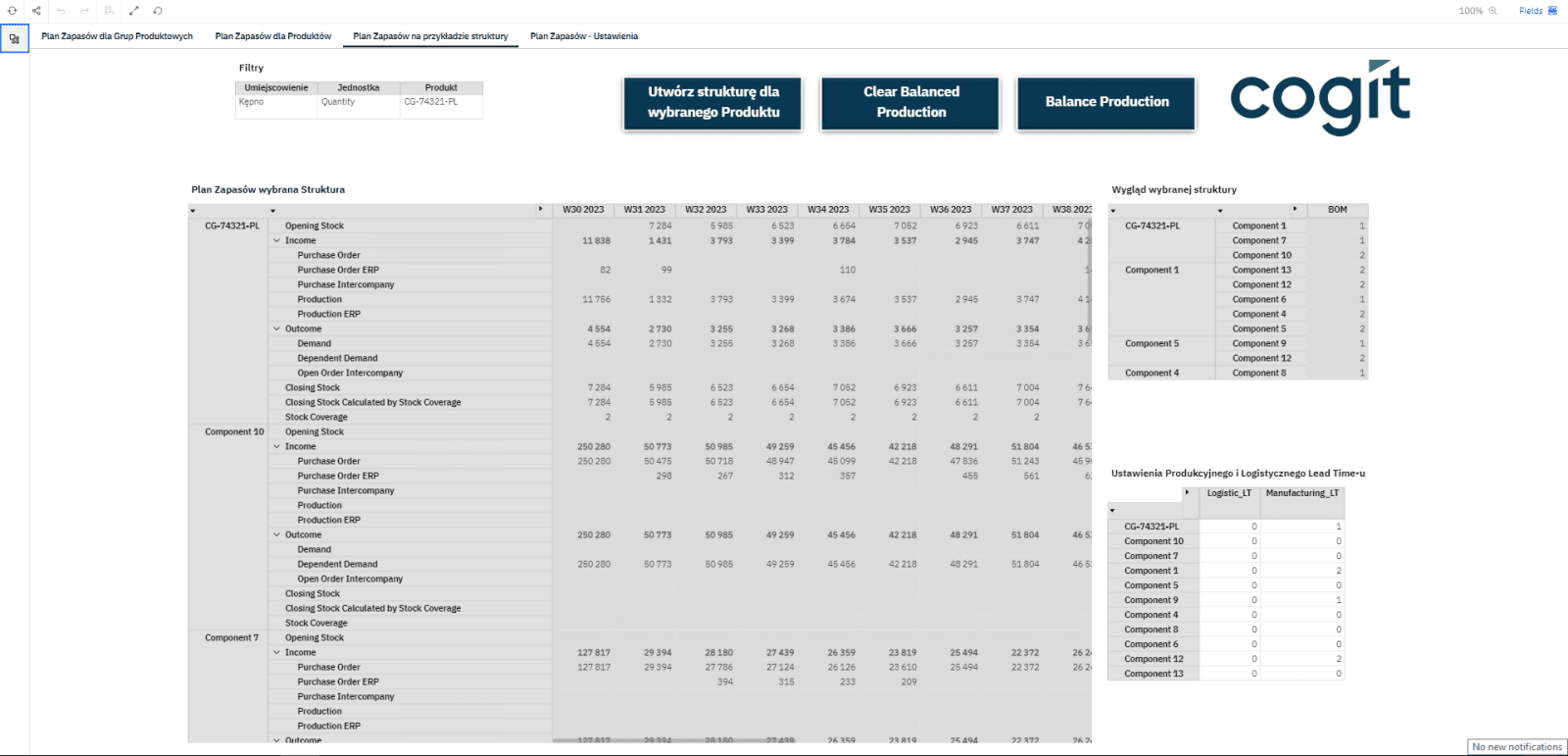

The warehouse planning module is the second in the S&OP process. Its main goal is to calculate inventory levels for future periods. An additional feature of this module is an algorithm that calculates potential purchase orders and production orders for products and components whose inventory is below 0 or the target level defined by the warehouse coverage degree. This module holds information about the product structure and possible LeadTimes causing time shifts.

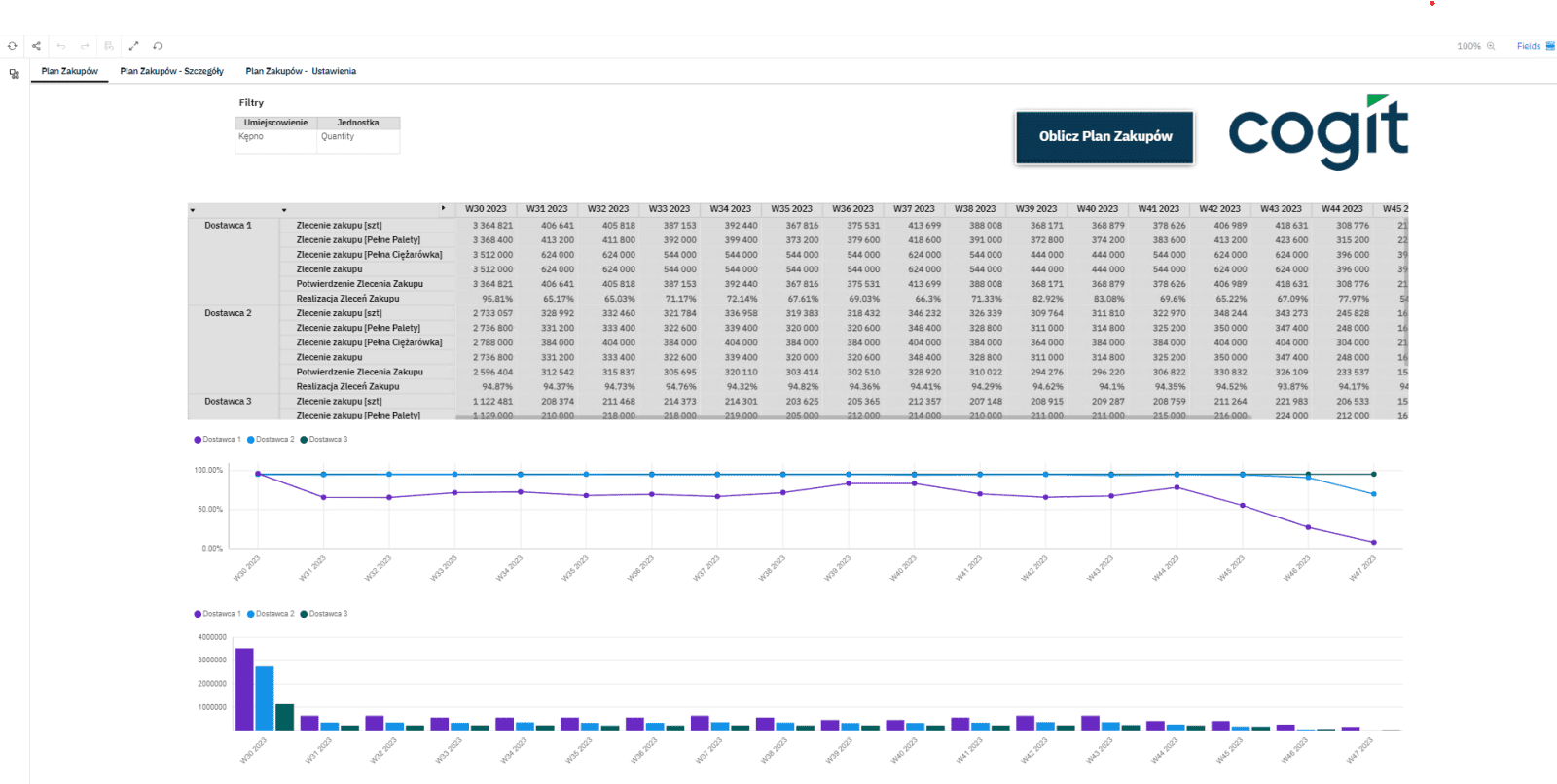

Procurement Planning

Enables effective management of the procurement process, efficient planning, and monitoring of purchase orders. Purchase order values are generated by a created algorithm or retrieved from the ERP system. The module allows forecasting future purchases for each supplier, taking contractual conditions into account. These data are collected and analyzed, allowing efficient supply management. The system generates a procurement plan for each supplier and for all purchase items, detailed views by supplier and product, providing an accurate overview of the quantity of purchase items needed to meet demand and the procurement plan for the product and supplier, considering pallet size, quantity of items per pallet, and the number of pallets fitting in a truck.

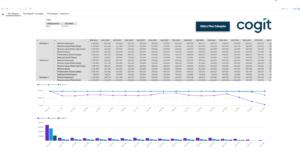

Resource Efficiency Planning

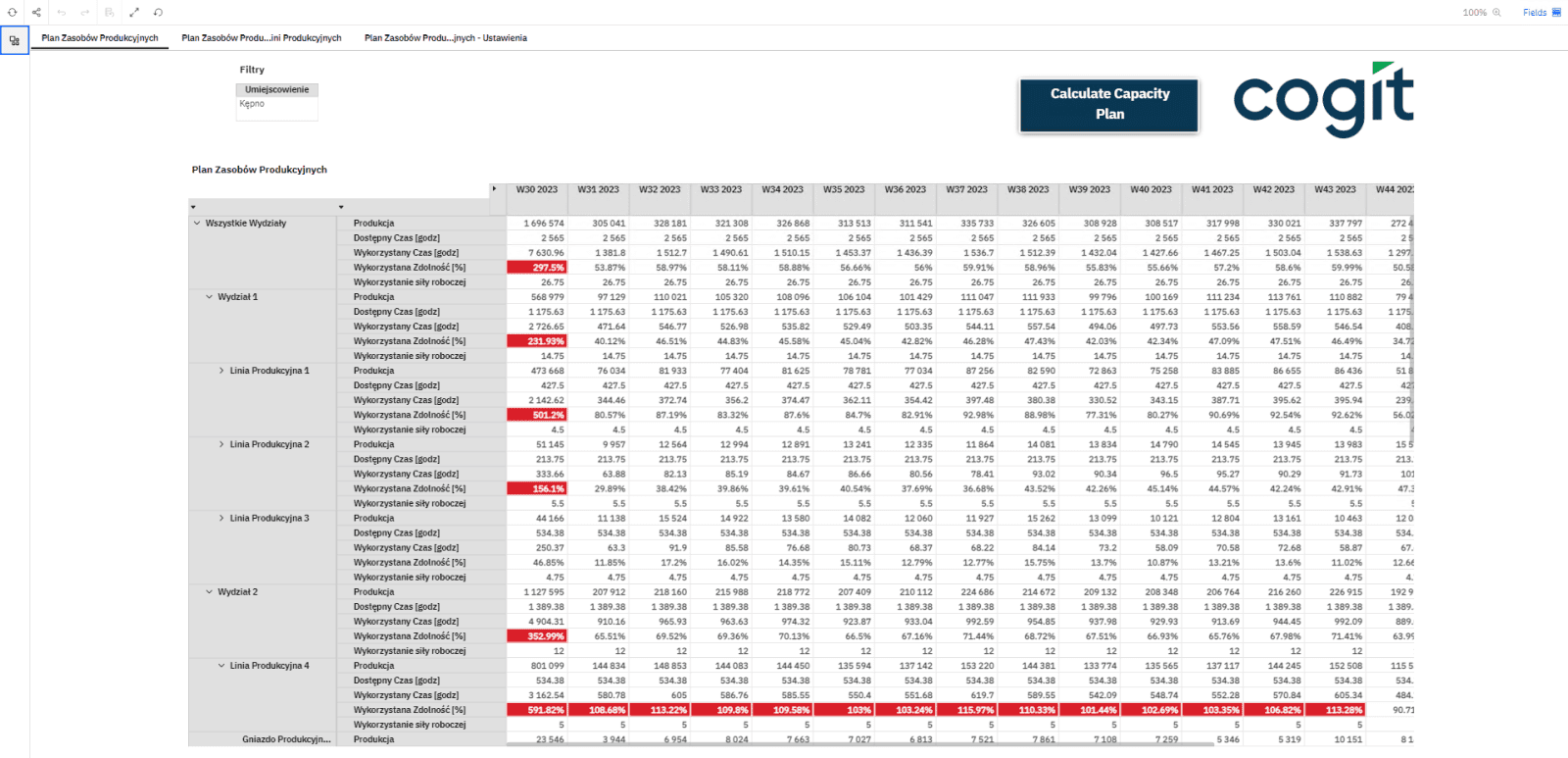

This module is responsible for forecasting the utilization of resources in the form of machines and personnel, based on orders created by the production algorithm or orders generated by the ERP system.

The efficiency plan includes planned utilization of production resources, taking into account working days and efficiency on each machine. The system generates performance analyses for individual departments, lines, and production nests, considering the number of available working days per week, efficiency, NEE, and the number of resources assigned to each production nest.

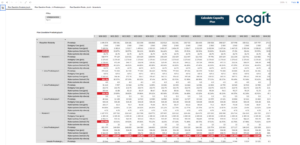

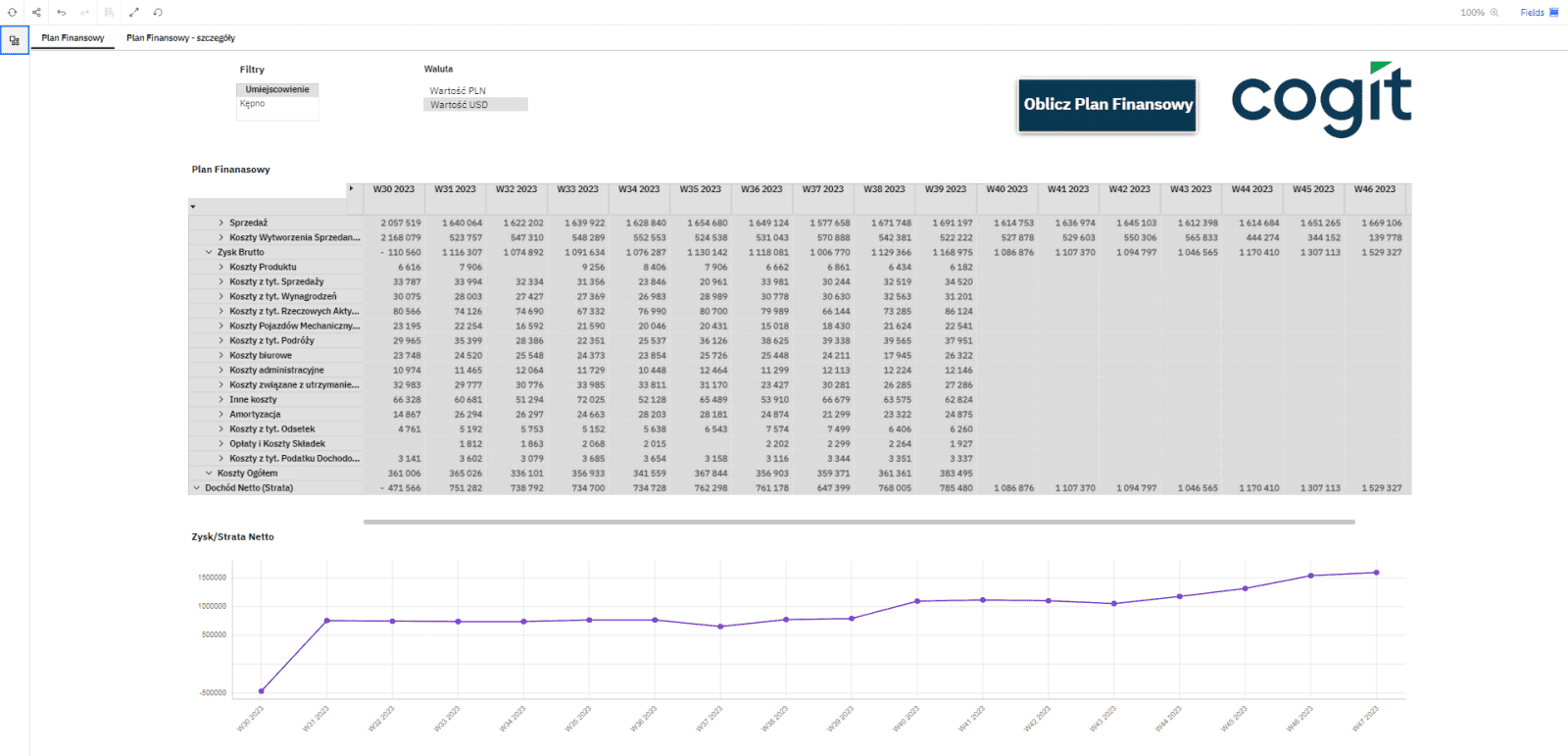

Financial Planning

Presents the current and forecasted financial situation of the enterprise. The module utilizes information about demand and production captured in the inventory management module. The system generates a general financial plan and linearly presents Net Profit/Loss, as well as a detailed financial plan containing all the company’s subaccounts.